Table of Contents

AI in logistics is driving a significant transformation within the industry, as companies increasingly adopt advanced technologies to streamline operations. By leveraging AI, businesses can enhance efficiency, lower costs, and elevate customer satisfaction. This powerful technology provides valuable insights that enable logistics providers to make informed decisions and optimize supply chain processes.

In this article, we will explore six innovative uses of AI in logistics, delving into the technologies that power these advancements, the cost implications of implementation, the sustainability benefits they offer, and the future trends shaping the logistics landscape.

6 Uses of AI in Logistics

1. Predictive Analytics for Demand Forecasting

AI in logistics leverages predictive analytics to improve demand forecasting. By scrutinizing historical data and current market conditions, AI algorithms can predict future demand with exceptional accuracy. This ability allows logistics companies to fine-tune their inventory levels, balancing supply and demand effectively.

Retailers can utilize AI to assess seasonal trends, sales patterns, and external influences like economic changes or weather. By doing so, businesses can minimize excess stock, reduce costs, and boost customer satisfaction through timely product availability.

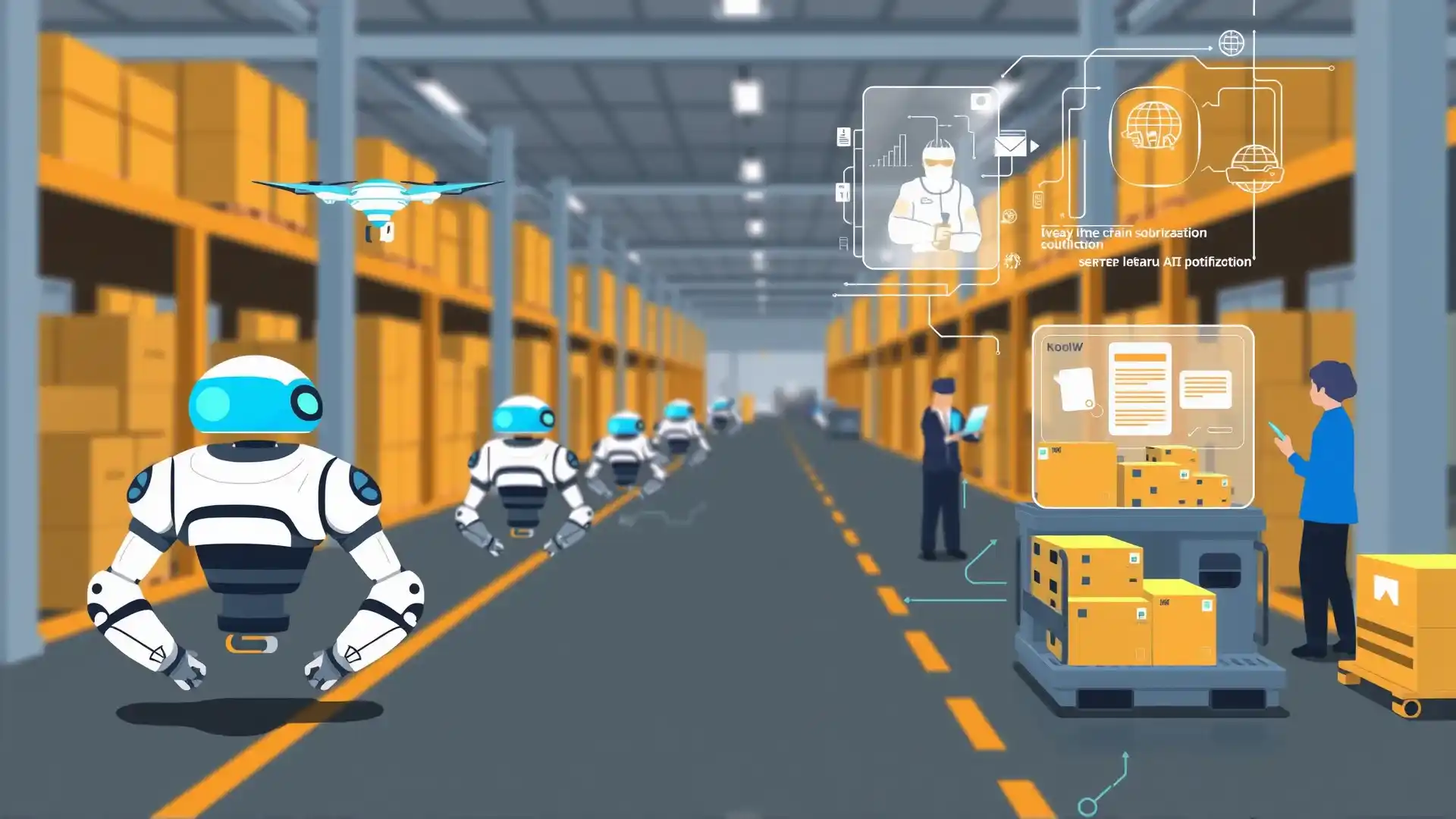

2. Autonomous Delivery Vehicles

The integration of AI in logistics includes the use of autonomous delivery vehicles, which represent a significant innovation. These self-driving vehicles, equipped with sophisticated sensors and AI algorithms, navigate complex environments seamlessly. They effectively transport goods from warehouses to consumers, especially in congested urban areas.

Major companies, including Amazon and UPS, are exploring autonomous drones and ground vehicles, which promise to enhance delivery speed, reduce labor expenses, and improve efficiency. As technology advances, the adoption of autonomous vehicles in logistics will expand.

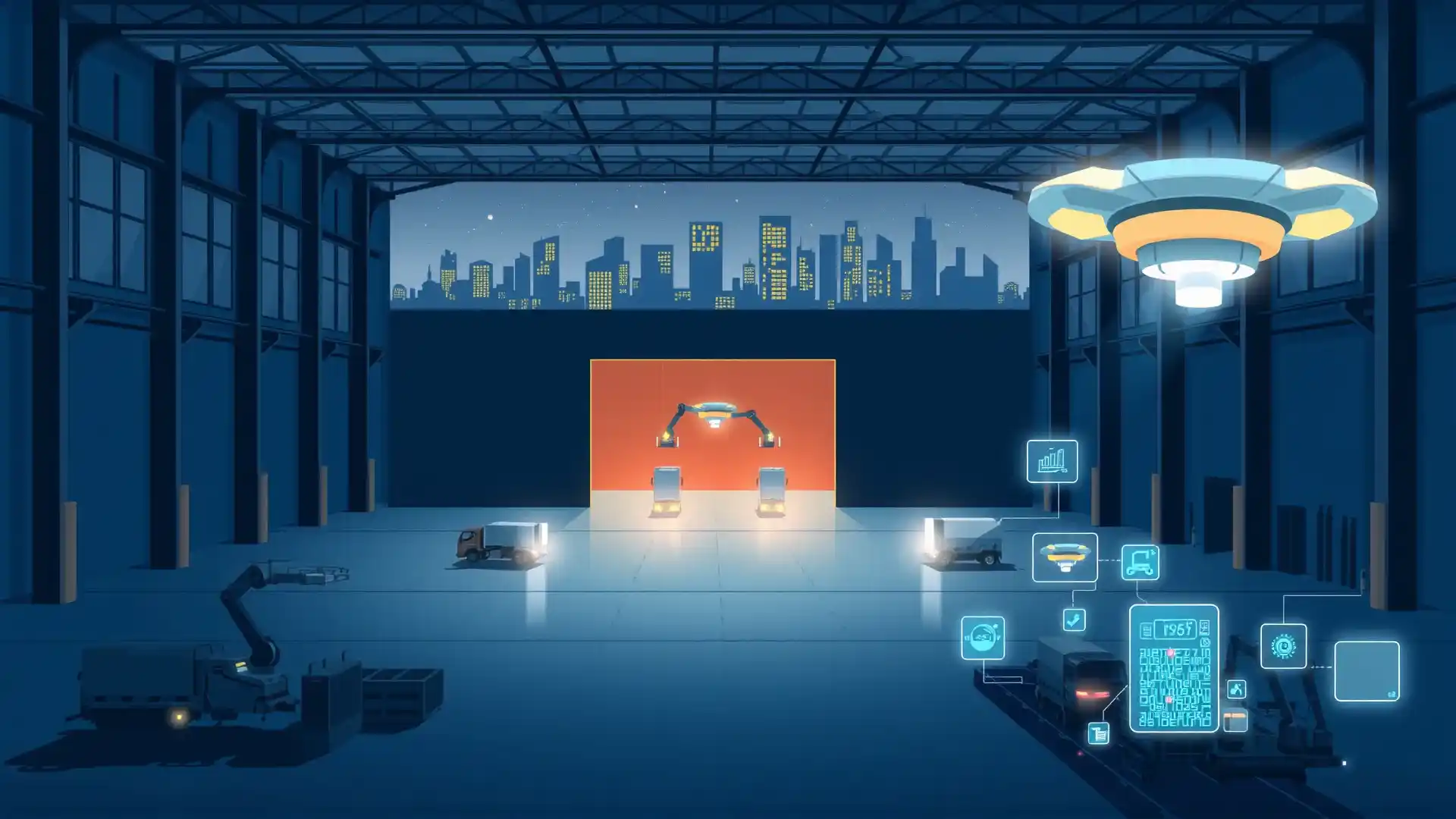

3. Smart Warehousing and Inventory Management

AI in logistics is transforming warehousing and inventory management through advanced technologies. Smart automated systems optimize storage, picking, and packing processes, leading to enhanced operational efficiency. AI algorithms work alongside robotics to automate repetitive tasks, minimizing manual labor and reducing human errors.

For instance, AI can continuously monitor inventory levels, predict restocking needs, and autonomously place orders with suppliers. This proactive management ensures warehouses maintain optimal stock levels while avoiding overstocking, ultimately lowering storage costs and enhancing operational performance.

4. Route Optimization and Planning

AI in logistics significantly enhances route optimization and planning. By analyzing traffic patterns, weather forecasts, and historical data, AI algorithms identify the most efficient delivery routes. This capability helps minimize transportation costs while reducing delivery times.

Moreover, AI-powered tools can dynamically adjust routes based on real-time traffic conditions, ensuring vehicles avoid congested areas. Such adaptability not only results in substantial fuel savings but also lowers the carbon footprint of logistics operations, ultimately improving operational efficiency and customer satisfaction.

5. Enhanced Customer Service through AI Chatbots

AI in logistics is revolutionizing customer service through the implementation of AI chatbots. These intelligent systems manage a variety of customer inquiries, including shipment tracking and delivery updates.

Utilizing natural language processing (NLP), chatbots engage with customers in real-time, delivering prompt responses and assistance. The incorporation of AI chatbots enhances customer satisfaction while lightening the workload on human service teams.

By automating routine queries, logistics companies can better allocate human resources to handle more complex customer needs, thus improving service quality.

6. Real-Time Tracking and Visibility

AI in logistics plays a crucial role in ensuring real-time tracking and visibility across the supply chain. With AI-powered systems, logistics providers can monitor shipments at each delivery stage, offering transparency to customers and stakeholders alike. This visibility enables rapid responses to potential disruptions, such as delays.

By utilizing AI algorithms to analyze diverse data sources, logistics companies gain valuable operational insights, enhancing decision-making. Ultimately, this capability fosters a more resilient and agile logistics network, capable of adapting to changing conditions.

Common Technologies Used in AI for Logistics

Various technologies are integral to implementing AI in logistics. These include:

- Machine Learning: Machine learning algorithms analyze historical data and learn from patterns to make predictions and optimize operations.

- Natural Language Processing (NLP): NLP enables chatbots to understand and respond to customer inquiries effectively.

- Computer Vision: Used in automated warehousing, computer vision helps robots identify and handle items accurately.

- Internet of Things (IoT): IoT devices collect real-time data on inventory levels, shipment conditions, and vehicle locations, feeding valuable information into AI systems.

Cost Implications of Implementing AI in Logistics

The cost of implementing AI in logistics can vary widely depending on the scale of the operation and the specific technologies used. While initial investments in AI solutions may be high, the long-term savings from improved efficiency, reduced labor costs, and enhanced decision-making often outweigh these expenses.

Companies must consider not only the upfront costs but also ongoing expenses related to maintenance, training, and integration with existing systems. However, with the potential for increased profitability and improved service delivery, many logistics companies find that the benefits of AI far exceed the costs.

AI and Sustainability in Logistics

AI can significantly contribute to sustainability in logistics. By optimizing routes and improving inventory management, AI reduces fuel consumption and waste. Additionally, predictive analytics helps companies better anticipate demand, minimizing overproduction and associated environmental impacts.

As businesses increasingly prioritize sustainability, the integration of AI in logistics provides a pathway to achieving greener operations while maintaining efficiency and profitability.

Future Trends in AI for Logistics

The future of AI in logistics is promising, with several trends likely to shape the industry:

- Increased Automation: The use of robotics and autonomous systems will continue to rise, further streamlining logistics operations.

- Enhanced Data Analytics: As data collection becomes more sophisticated, AI will leverage larger datasets to provide even more accurate predictions and insights.

- Greater Integration of IoT: The synergy between AI and IoT will enhance real-time visibility and tracking capabilities across the supply chain.

- Focus on Sustainability: Logistics companies will increasingly adopt AI solutions that support environmentally friendly practices, aligning with global sustainability goals.

Conclusion

AI in logistics is revolutionizing the industry, offering innovative solutions that drive efficiency, reduce costs, and enhance customer satisfaction.

By embracing these technologies, logistics companies can position themselves for success in a rapidly evolving market. As AI continues to advance, its impact on logistics will only grow, shaping the future of the industry.